I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

Mortar pump CM 150-T10

Electric motor power: 9.5 kW

Network operating voltage: 380 V, 50 Hz

Connection to the power grid: TN-S 230/380 V, 50 Hz

Screw Pump Type: T 10-1,5

Transport capacity: 120 l/min*

The size of the filler: 9 mm

Pressure in the transport hose: max. 3.0 MPa*

Transport distance: not more than 100 m*

Mixing spindle speed: about 400 min-1

Feed height: 80m

Feed range: 120 m

Main dimensions (LxWxH): 2300×765×650 mm

Total weight: about 180 kg

Funnel volume: 150 L

*depending on the type and viscosity of the solution mixture

Get spare parts catalog

Cleaning ball – 1 pc.

Vibrating screen – 1 pc.

Rotor T 10-1.5 – 1 pc.

Stator T 10-1.5 – 1 pc.

Additional hopper – 150 l

The transport capacity of the CM 150-T10 mortar pump is approximately 120 liters per minute and it can be changed using various screw pumps.

The principle of operation

The mortar pump is loaded manually or by gravity from the automatic mixer. A solution from an automixer with a volume of 5 cubic meters . m with the help of a mortar pump CM 150-T10 is pumped in 30-35 minutes.

To filter out large particles, a vibrating screen is provided in the design of the CM 150-T10 mortar pump. The total volume of the loading hopper is 300 liters, which makes the mortar pump more convenient.

The screw pump located in the funnel delivers the mortar through transport hoses directly to the place of its use. The feed height is about 80 m vertically and 120 m horizontally. The useful life of one screw pair (rotor + stator) is 650 cubic meters of solution.

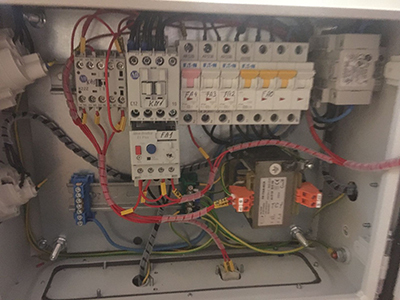

The electric distributor is equipped with a lock against restarting, which means that after a power outage, the CM 150-T10 mortar pump must be put into operation again (after removing the reason for the delay), for this you should press the green "I" button.

All electrical elements are in a waterproof and dust-proof box, which is mounted on the frame. All control components are conveniently accessible.

The frame of the CM 150-T10 mortar pump is made in the form of a funnel equipped with two wheels, which provides easy manipulation of the installation even in cramped rooms.

- With small dimensions, a large capacity of 7.2 m3/h

- Easy to manage and maintain

- All nodes are made of high-strength material

- All elements are from European manufacturers, including electrics

- Easy operation and maintenance

- T10-1.5(Germany)

- Capacity 7 m3/hour

Bunker

- Useful volume of 250 liters with built-in vibrating screen

Electrical panel

- All electrics are made in Europe

- Thoughtful and convenient management

Gear motor

- The 7.5 kW European gear motor will ensure a long service life

Exit

- Solution sleeve DN50 40 atmospheres

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.