I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

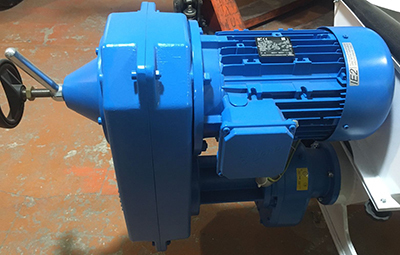

Shotcrete installation CM 40

Motor power: 5.5 KW

Operating voltage: 400 V, 50 Hz

Power connection: TN-S 230/400 V, 50 Hz

Current consumption: 11.1 A

Screw Pump Type: 2L6

Transport capacity: 40 l/min*

Pressure in the transport hose: max. 3.0 MPa*

Output power of the compressor: about 550 l/min

Vertical transport distance: 50 m

Horizontal transport distance: 70 m

Mixing screw speed: about 400 min -1

Main dimensions (LxWxH): 1570x570x575 mm

Total weight: about 120 kg

Funnel volume: 40 L

Get spare parts catalog

Air hose L=10 m – 2 pcs.

Cleaning ball – 2 pcs.

Compressor – 1 pc.

Shotcrete gun – 1 pc.

Mechanical variator – 1 pc.

Electrical panel – 1 pc.

Rotor 2L6 – 1 pc.

Stator 2L6 – 1 pc.

The simple and lightweight design and placement of individual components ensure comfortable maintenance and repair and contribute to the overall reliability of the plastering station. The station for wet shotcrete CM 40 5.5 kW includes a compressor with a capacity of 550 l/min. Receiving hopper with a capacity of 40 liters.

The principle of operation

The station for wet shotcrete CM 40 5.5 kW is loaded on the move with a mixed composition from a stirrer.

The screw pump delivers the mortar with transport hoses to the plaster gun, from where it is sprayed with air onto the plastered surface. The necessary air supply is provided by a diaphragm compressor, which is located in the front of the unit, an air-conducting hose is carried out together with a hose to supply the mortar to the plaster gun. During operation, the station for wet shotcrete CM 40 5.5 kW is operated pneumatically from a plaster gun. By closing the air valve on the plaster gun, the pressure rises in the air-conducting hose, which turns off the plaster station with the help of a pressure switch.

The electrical switchgear is equipped with a re-start lock, which means that after the power outage that caused the plaster station to stop, it is necessary to put the unit back into operation (after eliminating the cause of the stop) by pressing the green "I" button.

All electrical elements are located in a waterproof and dust-proof box, which is attached to the frame, which gives easy access to all controls and sockets.

The frame of the station for wet shotcrete CM 40 5.5 kW is made of a lightweight tubular structure equipped with two wheels, which makes it easy to handle the plaster unit in cramped rooms.

- High performance

- Powerful compressor

- Ease of construction and maintenance

- Simple maintenance and repair

- Convenient and easy cleaning of the machine

- Small loading height

- High corrosion resistance

- Clear instructions

- Smooth flow control thanks to a reliable mechanical variator

- Variator gear motor NORD (Germany)

- Service life of at least 10 years

- Smooth adjustment of capacity up to 2.4 m3/hour

Compressor

- Stand-alone electrical equipment with Delta2 compressor

Bunker

- Made of high-strength sheet metal

Gerotor pair

- 2L6 (Germany) tightened

- Resource up to 600 m3

Exit

- Solution sleeve DN35 40 atmospheres

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.