I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

I want to get a spare parts catalog!

Send a request and get the catalog to your e-mail

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.

MPCS 4 ECO shotcrete installation

Rotary drum - 9 cells;

Volume - 4.8 dm3;

Electric motor power - 4 kW;

Power supply system - 3x380 V + PEN 50 Hz;

Grain size transp. material:

- 8 mm for layer thickness up to 50mm;

- 16 mm for a layer thickness of more than 50mm

Transport distance :

Horizontally - 80 – 250 m for bulk materials,

80 – 150 m for concrete mortars;

Vertical - 28 – 30 m for bulk materials,

25 - 28 m for concrete mortars;

Dimensions, L*W*H: 1.26 m *0.84 m *1.2 m;

Weight: 650 kg.

Get spare parts catalog

- To strengthen the walls of construction objects

- Transportation and application of dry mixes on walls

- Concreting of slopes

- Repair of bridge supports

- Waterproofing works

- Application of refractory concrete to the walls of steel ladles

-Bottom sealing disc 1 piece;

-Gun for shotcrete;

-Hose DN 40mm - 20 m;

-Water hose DN 19mm - 20 m.

The massive design and placement of individual components allow for comfortable work and increase the reliability of the equipment.

The MPCS 4 ECO shotcrete unit is designed for feeding and applying dry concrete mixtures to tunnel walls, during the restoration of bridge supports, for waterproofing concreting works, for delivering and applying heat-resistant concrete to the walls of a steel furnace, ladle, which may be at operating temperature or may be cooled.

The MPCS 4 ECO shotcrete unit is equipped with massive wheels and a front steerable wheelset, which allows it to be manipulated conveniently. If the MPCS 4 ECO Shotcrete unit is used in a stable workplace, it can be installed without a running gear with a device for manipulation using a high-lift trolley.

The MPCS 4 ECO shotcrete unit is loaded with a mixture from bags or with the help of an auxiliary structure, from high-volume bags (of the "Big-Run" type).

The principle of operation

The mixture supplied in bags should be loaded into the funnel. The funnel is equipped with a vibrator, which contributes to a good loading of the mixture into the chambers of the dosing turnstile. By rotating the turnstile, the chamber filled with the mixture enters the position in which compressed air pushes it into the ejector. In the ejector, the mixture is pushed with the following air through the transport hose into the cement gun, where the dry mixture is moistened with sprayed water and after that the mixture is thrown out with concrete to the treated place. The mixture is applied at high speed, which allows to obtain excellent adhesion on the treated surface.

- High quality proven over the years

- Produced for more than 20 years

- The leader of sales in the Russian market

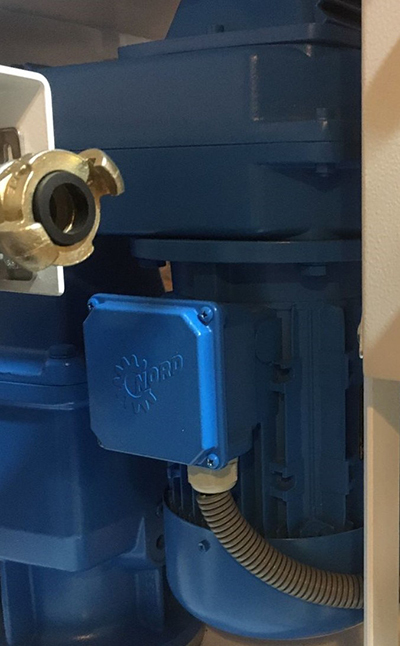

- The mechanical variator NORD will allow you to adjust the performance correctly

- Service life of at least 10 years

- Variator gear motor NORD (Germany)

- Power 4 kW

- Smooth performance adjustment

Receiving hopper

- Volume 60 l

- Built-in pneumovibrator

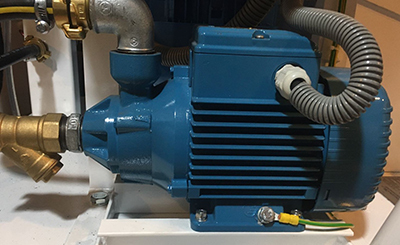

Water pump

- Production Italy

- It will provide a homogeneous consistency of the mass at the output

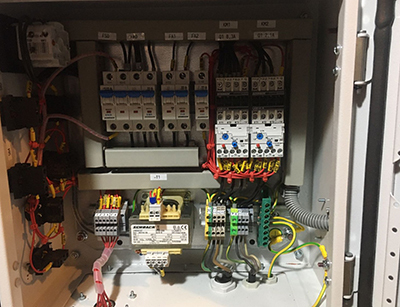

Electrical panel

- European electrical equipment

- Convenient access

- Remote control

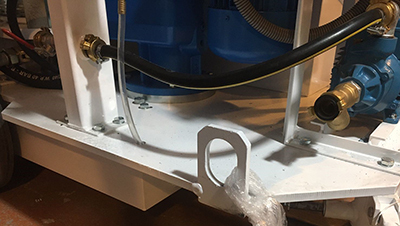

Frame

- The stability of the entire structure is provided by a reinforced metal plate with a thickness of 1.5 cm

By clicking on the «Submit application» button, you consent to the processing of your personal data in accordance with the privacy policy.